strain hardness test|hardness test examples : exporter Hardness Testing. Hardness testing involves pushing a hard indenter into a sample with a known force and measuring the size of the residual indent. Different types of hardness test differ only in the shape and size of the . WEB26 de dez. de 2022 · I believe the storage slot values in the EVM limited to 256 bits mainly because this facilitates Keccak256 hash scheme and elliptic-curve computations. Also, .

{plog:ftitle_list}

20 de jun. de 2019 · Mouse auto clicker is a free auto clicker, free mouse clicker, and free auto post. Running on MS Windows with.NET framework support. Definitely, This is a free auto clicker tool. How to get Mouse Auto Clicker: - CASE Firs time use: + Go to home page https://www.mouseautoclicker.org/ + Click "Create Profile" + Enter First Name, Last Name,

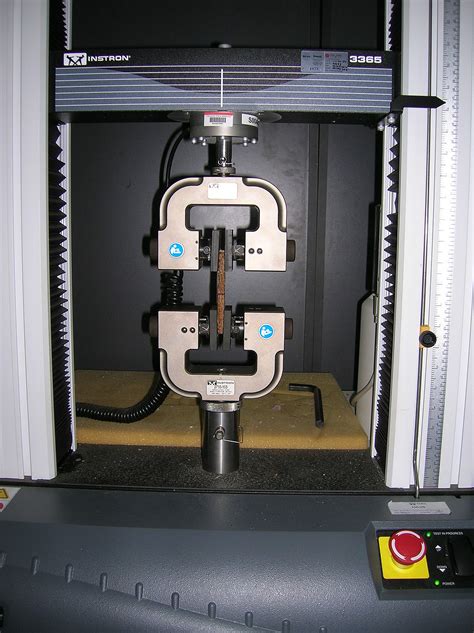

Hardness Testing. Hardness testing involves pushing a hard indenter into a sample with a known force and measuring the size of the residual indent. Different types of hardness test differ only in the shape and size of the .Strain-Hardness Correlation Testing Technique. A new material analysis technique was developed at the MSFC Materials & Processes Lab to efficiently generate correlation curves .Perhaps the most important test of a material’s mechanical response is the tensile test (Stress-strain testing, as well as almost all experimental procedures in mechanics of materials, is . The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the .

This work concerns the use of two indentation-based test procedures to infer features of the (nominal) stress-strain curve, as obtained via conventional tensile testing. .

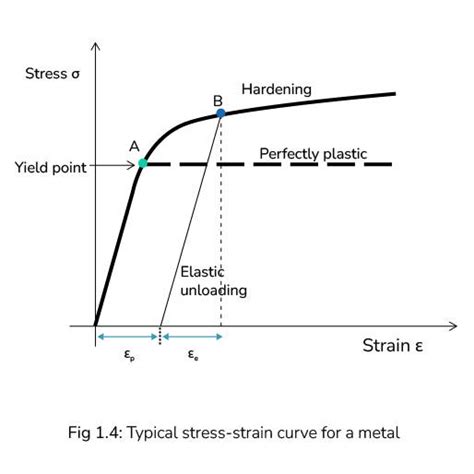

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strain. It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress .Hardness Testing. Discover the intricate world of hardness testing in materials engineering. This comprehensive guide delves into the definition, standards, procedure, and vital . There are five commonly-used methods of hardness testing: (a) Brinell hardness test, (b) Rockwell hardness test, (c) Vickers test, (d) Knoop hardness test, and (e) .

Standardized optical hardness testing methods include the Brinell hardness test (ISO 6506, ASTM E10), Knoop hardness test (ISO 4545, ASTM E92, ASTM E384) and Vickers hardness test (ISO 6507, ASTM E92, ASTM E384).

A hardness test is a non-destructive test which measures the resistance of a material to local permanent shape change by an indenter under a static load, and gives an approximate . The uniaxial tensile test is the most commonly-used mechanical testing procedure. However, while it is simple in principle, there are several practical challenges, as well as a number of points to be noted when . Based on the power-law stress–strain relation and equivalent energy principle, theoretical equations for converting between Brinell hardness (HB), Rockwell hardness (HR), and Vickers hardness (HV) were established. .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

The resulting strain-hardness correlation curve is a tool to inform other material evaluations by providing a calibration between . Strain-Hardness Correlation Testing Technique Innovative Techniques 29 Local Strain Hardness (d) (b) (a) Overlay of DIC data on test specimen.Young’s modulus is equal to the longitudinal stress divided by the strain. Hardness of 6061 Alloy. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load .One of stages in the stress-strain curve is the strain hardening region.This region starts as the strain goes beyond yield point, and ends at the ultimate strength point, which is the maximal stress shown in the stress-strain curve.In this region, the stress mainly increases as material elongates, except that there is a nearly flat region at the beginning.The testing machine keeps the closed loop strain rate constant by using an extensometer to continuously provide strain values that are used to calculate the precise strain rate. The standard specifies a strain rate of 0.015 ± 0.006 in./in./min or mm/mm/min , which corresponds to a tolerance of 40% when setting the strain rate.

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The . A schematic diagram for the stress-strain curve of low carbon steel at room temperature is shown in the figure. There are several stages showing different .

tensile stress strain testing

tensile strength testing

Silver has wide-ranging applications, such as industrial equipment, semiconductors, musical instruments, and silverware. Despite its diversified applications, publications on its strain-hardening characteristics are rare. In this work, tensile and hardness tests were performed for cold-rolled specimens at different levels of thickness reduction after .

A phenomenological uniaxial stress–strain curve showing typical work hardening plastic behavior of materials in uniaxial compression. For work hardening materials the yield stress increases with increasing plastic deformation.The strain can be decomposed into a recoverable elastic strain (ε e) and an inelastic strain (ε p).The stress at initial yield is σ 0.

Young’s modulus is equal to the longitudinal stress divided by the strain. Hardness of Ductile Cast Iron – ASTM A536 – 60-40-18. . and water generally increases with hardness. Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, .

Hardness = ability of a material to resist plastic deformation. Note that the sketch reflects two hypothetical (imaginary) material curves. Many other stress-strain curve profiles are possible. Also note that the description of toughness presented here is based on general material toughness, which is only one way to assess toughness.

Tensile strength is the material’s resistance to breaking while under tension, which is a function of stress and strain as well as the cross-section of the material. It can be measured using a tensile tester. . Common concerns with hardness testing are accuracy and repeatability. Hardness is extrapolated from the depth measured, which then .well as tension, hardness, torsion, and impact tests in particular. Mechanical Testing Mechanical tests (as opposed to physical, electrical, or other types of tests) often . ( LVDT's) for stroke of the test machine), strain (e.g., clip-on strain-gaged based extensometers). In addition, controlled environments can also be applied throughTesting Epoxy for Hardness. Hardness is a measure of how hard the surface of a substance is. The harder the surface of a coating is, the more abrasion-resistant it is. . Tensile elongation is the change in length of a sample (strain) when loaded to failure. This value is measured at the breaking point, or when the sample has been stretched .Young’s modulus is equal to the longitudinal stress divided by the strain. Hardness of Beryllium Bronze. Rockwell hardness of copper beryllium – UNS C17200 is approximately 82 HRB. Rockwell hardness test is one of the most .

The ultimate tensile strength and 0.2% yield strength of this steel correlated well with hot microhardness data at test temperatures up to 400°C using Cahoon's expressions sigmauts = (H/2.9)(n/0. .Young’s modulus is equal to the longitudinal stress divided by the strain. Hardness of Titanium Grade 2. Rockwell hardness of commercially Pure Titanium – Grade 2 is approximately 150 HRB. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test .

For the Knoop hardness test, the two halves of the long diagonals must not differ by more than 10.0% from each other. Show More. Solution: . If the hardness indentations are too close to each other, strain hardening can appear. A FULL RANGE OF .Hardness testing is accomplished by lowering a probe with a hard (typically diamond) tip onto a material at a set force and measuring the amount of indentation that the probe (the indentor) produces (depth of plastic deformation). . Shear Strain: deformations that occur parallel to the cross-section; shear strain is caused by shear stress .E646-16 Standard Test Method for Tensile Strain-Hardening Exponents (n-Values) of Metallic Sheet Materials . . Indentation Hardness Testing. E140-12B(2019)e1 Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and .

Yield and ultimate strengths can be determined from the stress-strain curve of a material, that is obtained by performing a tensile test. The yield and ultimate strengths on a stress-strain curve Many structures and components are design to ensure that they only deform elastically (i.e. there is no permanent deformation after the applied load . Both hardness testing and Profilometry-based Indentation Plastometry (PIP) can be used to obtain features of (tensile) stress-strain curves. The two tests are superficially similar, involving penetration (under a known load) of an indenter into the flat surface of a sample, followed by measurement of dimensional characteristics of the residual indent.Common methods to measure strain hardening in materials include tensile testing to assess stress-strain behavior, hardness testing to evaluate surface deformation resistance, and nanoindentation for precise measuring of material properties at micro and nano scales. Microstructural analysis like electron microscopy can also provide insights into .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The . A schematic diagram for the stress-strain curve of low carbon steel at room temperature is shown in the figure. There are several stages showing different .The Meyer hardness test is a hardness test based upon projected area of an impression. . For annealed materials the Meyer hardness increases continuously with load due to strain hardening. [2] Based on Meyer's law hardness values from this test can be converted into Brinell hardness values, .

Stress-Strain Diagram is determined by tensile test. Tensile tests are conducted in tensile test machines , providing controlled uniformly increasing tension force, applied to the specimen. The specimen’s ends are gripped and fixed in the machine and its gauge length L 0 (a calibrated distance between two marks on the specimen surface) is .

strain hardening curve diagram

plastic hardness test

19 de mar. de 2023 · Fim do segundo tempo, Nice 1, Lorient 1. 50'. Falta cometida por Dante (Nice). Julien Ponceau (Lorient) sofre uma falta no campo defensivo. Finalização bloqueada, Adil Aouchiche (Lorient .

strain hardness test|hardness test examples